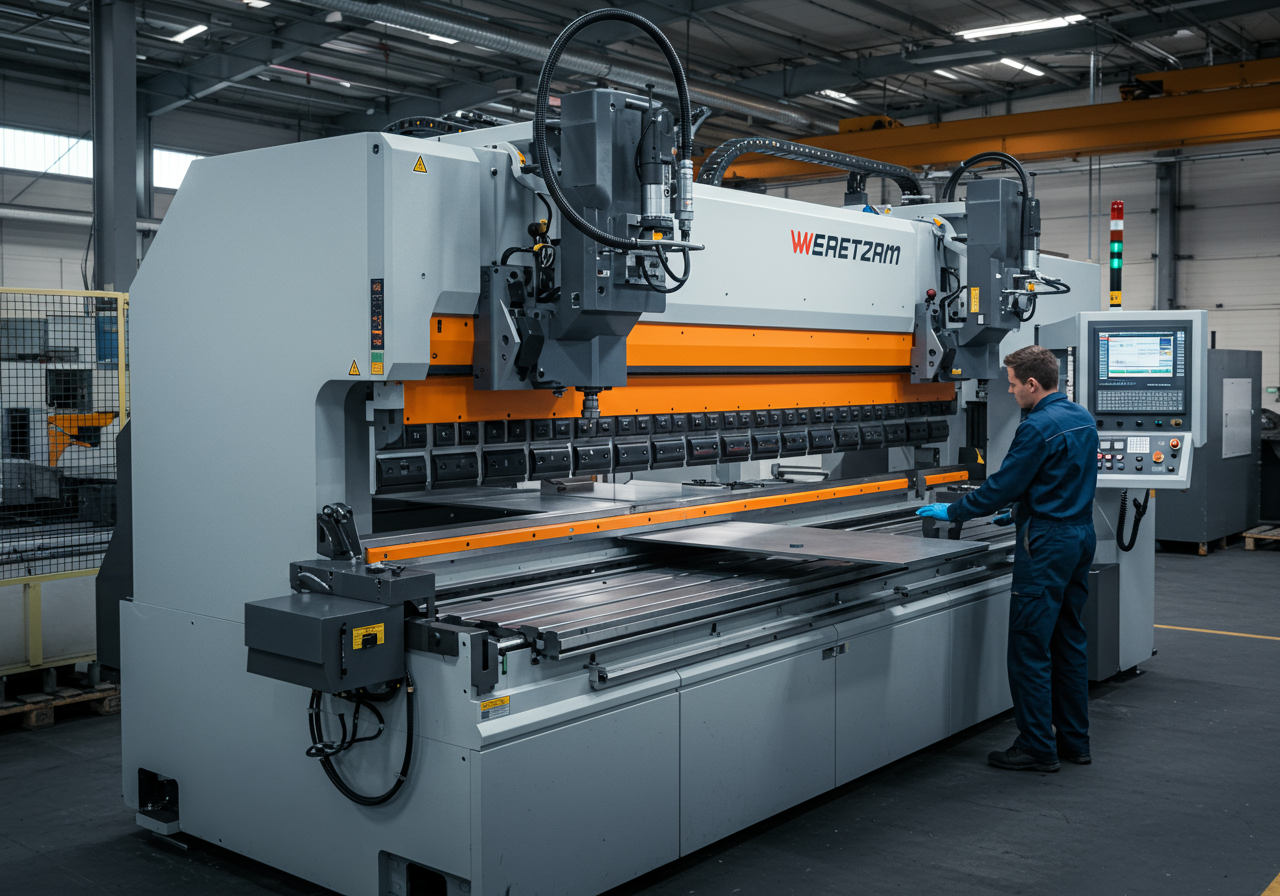

Premier Automated Sheet Metal Bending & Shearing Machines

Premier Sheet Metal Bending & Shearing by TC Smart Technology

Headquartered in Delhi NCR - Noida, TC Smart Technology delivers cutting-edge automated sheet metal bending and shearing machines with advanced robotics, IoT connectivity, and ±0.01 mm precision. Our comprehensive solutions redefine fabrication for global industries.

Get in Touch

Why Choose TC Smart Technology?

From Delhi NCR - Noida, we provide innovative bending and shearing machines with AI-driven precision, IoT integration, and up to 50% energy savings, ensuring scalability, efficiency, and Industry 4.0 compliance.

Ultra-Precision

Bending accuracy of ±0.01 mm.

Robotic Automation

6-axis robots reduce cycle times by 40%.

Energy Efficiency

Up to 50% energy savings with servo systems.

Our Sheet Metal Bending & Shearing Machines

A diverse range of new, specialty, and affordable machines for all sheet metal fabrication needs.

CNC Press Brakes

Up to 6,000 kN for complex geometries.

Servo-Electric Press Brakes

50% energy savings for precision bending.

Hydraulic Press Brakes

Heavy-duty bending up to 20 mm thick.

Panel Benders

30-second cycles for large panels.

Guillotine Shears

Clean cuts for sheets up to 25 mm.

Turret Punch Presses

1,200 hits per minute for intricate patterns.

Specialty Fabrication Equipment

Advanced solutions for unique sheet metal challenges.

- Robot Integration: 6-axis arms for 40% faster cycles.

- IoT Connectivity: 25% less waste with analytics.

- AI Optimization: 20% better bend accuracy.

- Laser-Guided Shearing: ±0.1 mm cut precision.

- Hybrid Systems: Servo-hydraulic for high-force tasks.

- Adaptive Control: Dynamic force adjustment.

Industry-Specific Solutions

Tailored fabrication solutions for diverse industries.

- Aerospace: ±0.01 mm titanium airframes.

- Automobile: 40% faster body panel bending.

- Medical: ISO 13485-compliant tool housings.

- Jewellery: 0.05 mm micro-shearing.

- Electronics: EMI-shielded enclosures.

- Infrastructure: Structural beam fabrication.

- Oil & Gas: Corrosion-resistant fittings.

- Power: Wind turbine base forming.

- Railways: Railcar frame bending.

- Telecom: Antenna mount precision.

- Agriculture: Harvester part durability.

- Die & Mould: 60 HRC mold bases.

Technical Highlights

Advanced features driving our fabrication solutions.

- Bending Capacity: 50 to 6,000 kN.

- Shearing Capacity: Up to 25 mm thick.

- Precision: ±0.01 mm bending accuracy.

- Controls: Siemens, Fanuc with OPC UA.

- Automation: 6-axis robots and tool changers.

- Materials: Steel, titanium, composites.

End-to-End Support

Complete solutions with machines, training, and 24/7 support.

Installation & Setup

Expert setup for seamless integration.

Operator Training

AR-based training for CNC programming.

24/7 Support

Rapid response with <4-hour downtime.

Why Our Fabrication Solutions?

Transform your operations with precision and efficiency.

High Precision

Tolerances as tight as ±0.01 mm.

Enhanced Productivity

50% faster cycles with automation.

Cost Efficiency

Affordable machines with high ROI.

Material Versatility

Steel, aluminum, titanium, composites.

Revolutionize Your Fabrication

Ready to transform your production with our automated sheet metal bending and shearing solutions? Contact TC Smart Technology at info@tcsmarttechnology.com or visit us in Delhi NCR - Noida.

Contact Us NowContact Information: Email: info@tcsmarttechnology.com | Location: Delhi NCR - Noida