Premier Hydraulic & Servo Power Press Machines

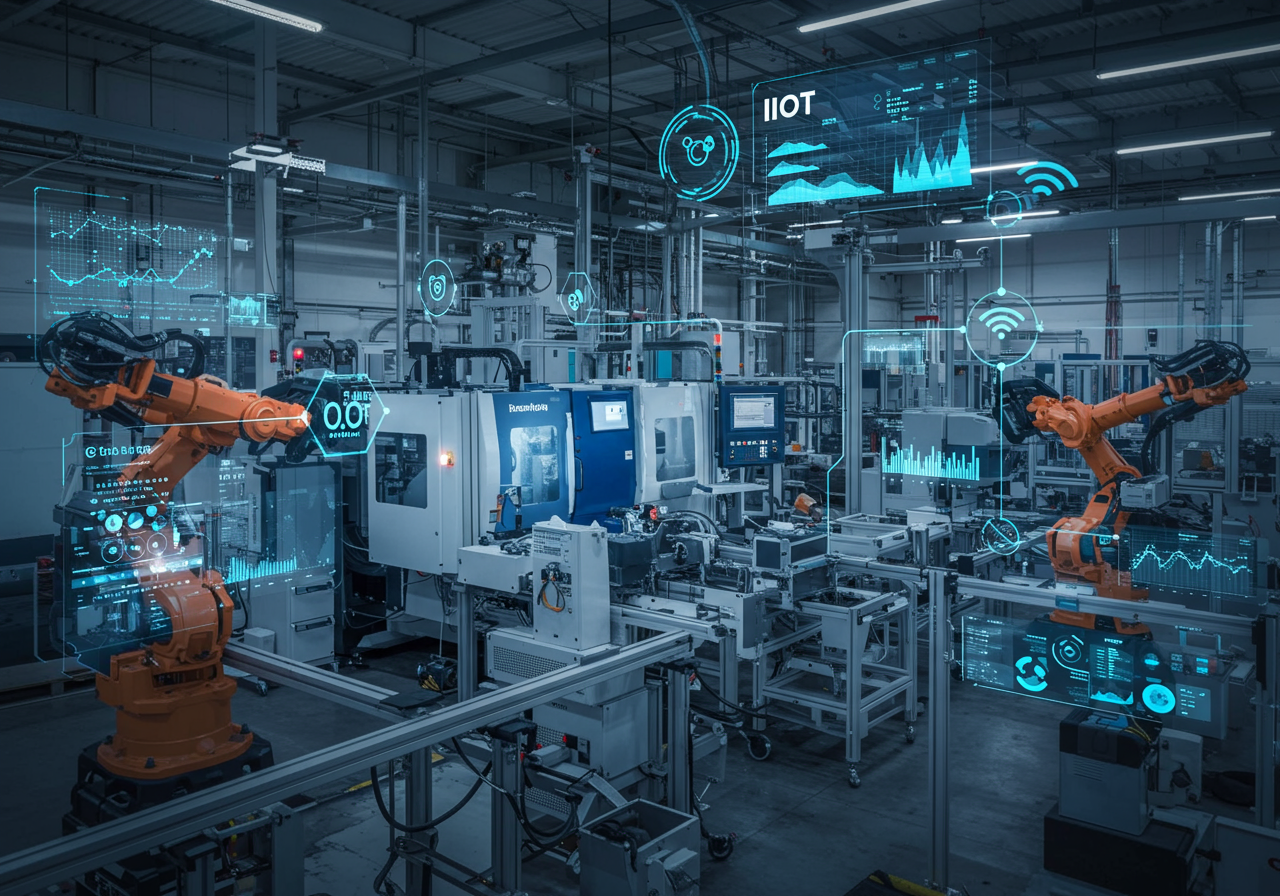

Premier Hydraulic & Servo Power Press by TC Smart Technology

Headquartered in Delhi NCR - Noida, TC Smart Technology delivers cutting-edge hydraulic and servo power press machines with advanced robotics, IoT connectivity, and ±0.01 mm precision. Our comprehensive solutions redefine metal forming for global industries.

Get in Touch

Why Choose TC Smart Technology?

From Delhi NCR - Noida, we provide innovative press machines with servo-driven precision, IoT integration, and up to 40% energy savings, ensuring scalability, efficiency, and Industry 4.0 compliance.

Ultra-Precision

Stroke control down to ±0.01 mm.

Robotic Automation

6-axis robots reduce cycle times by 40%.

Energy Efficiency

Up to 40% energy savings with servo systems.

Our Hydraulic & Servo Power Press Machines

A diverse range of new, specialty, and affordable machines for all metal forming needs.

Hydraulic Presses

Up to 5,000 tons for heavy-duty forming.

Servo Power Presses

0.5-second cycles for high-speed stamping.

C-Frame Presses

Compact design for small-scale operations.

H-Frame Presses

High stability for heavy components.

Four-Column Presses

Uniform force for deep drawing.

Knuckle-Joint Presses

Precision coining for electronics.

Specialty Press Equipment

Advanced solutions for unique manufacturing challenges.

- Robot Integration: 6-axis arms for 40% faster cycles.

- IoT Connectivity: 30% less downtime with analytics.

- Hybrid Systems: Servo-hydraulic for dynamic control.

- High-Speed Servo: 1,000 mm/s ram speeds.

- Multi-Station Presses: Sequential operations in one setup.

- AI Optimization: 25% faster cycle times.

Industry-Specific Solutions

Tailored press solutions for diverse industries.

- Aerospace: ±0.02 mm titanium airframes.

- Automobile: 40% faster body panel stamping.

- Medical: ISO 13485-compliant tool housings.

- Jewellery: 0.1 mm coining precision.

- Electronics: EMI-shielded enclosures.

- Infrastructure: Structural beam forming.

- Oil & Gas: Pipeline fittings.

- Power: Wind turbine bases.

- Railways: Railcar frame forming.

- Telecom: Antenna mount precision.

- Agriculture: Tractor frame durability.

- Die & Mould: 60 HRC mold bases.

Technical Highlights

Advanced features driving our press solutions.

- Press Capacity: 50 to 5,000 tons.

- Precision: ±0.01 mm stroke accuracy.

- Controls: Siemens, Mitsubishi with OPC UA.

- Automation: 6-axis robots and die changers.

- Materials: Steel, titanium, composites.

- Energy Savings: Up to 40% with servo drives.

End-to-End Support

Complete solutions with machines, training, and 24/7 support.

Installation & Setup

Expert setup for seamless integration.

Operator Training

AR-based training for press programming.

24/7 Support

Rapid response with <4-hour downtime.

Why Our Press Solutions?

Transform your operations with precision and efficiency.

High Precision

Tolerances as tight as ±0.01 mm.

Enhanced Productivity

50% faster setup with automation.

Cost Efficiency

Affordable machines with high ROI.

Sustainability

25% less energy with eco-friendly systems.

Revolutionize Your Manufacturing

Ready to transform your production with our hydraulic and servo power press solutions? Contact TC Smart Technology at info@tcsmarttechnology.com or visit us in Delhi NCR - Noida.

Contact Us NowContact Information: Email: info@tcsmarttechnology.com | Location: Delhi NCR - Noida