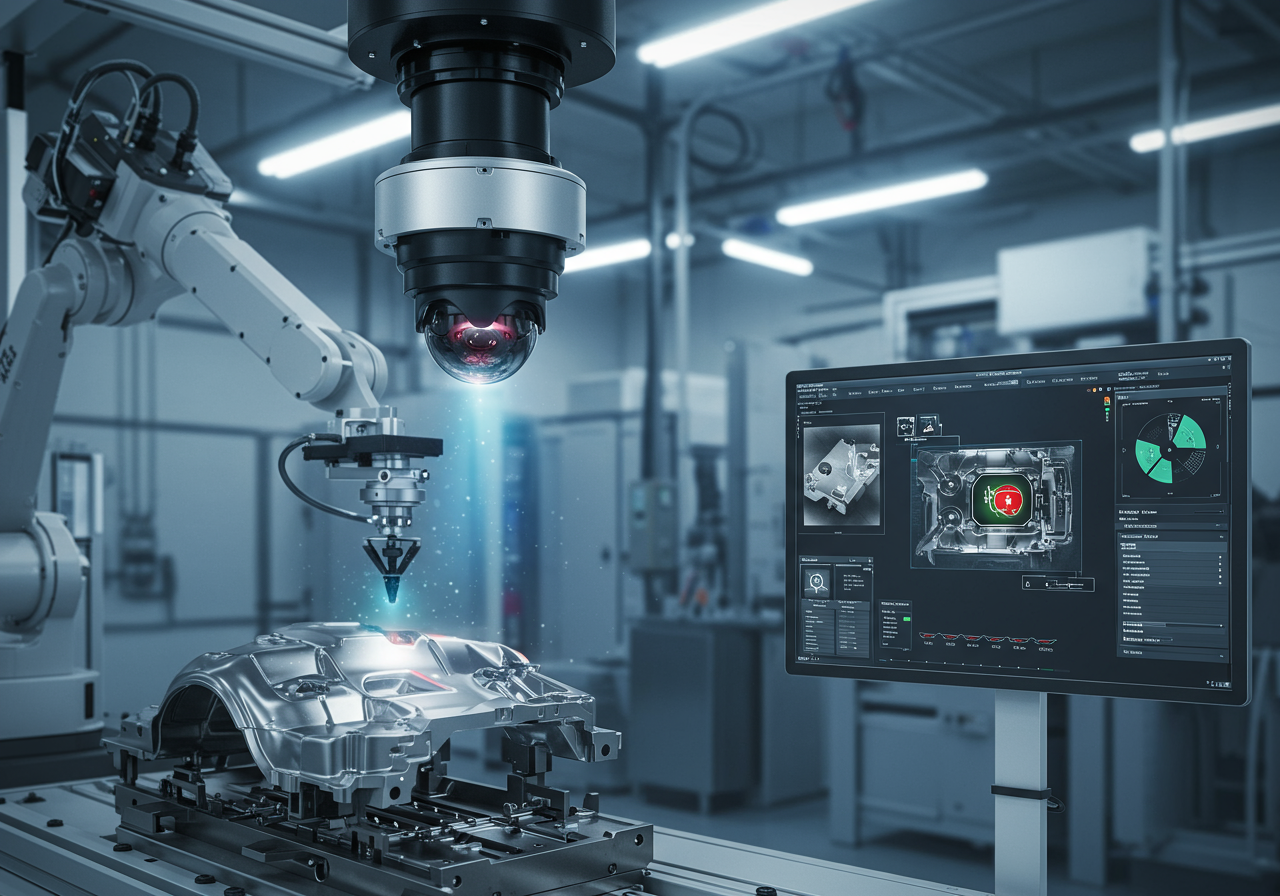

Machine Vision & Quality Inspection Systems

Premier Machine Vision & Quality Inspection by TC Smart Technology

Headquartered in Delhi NCR - Noida, TC Smart Technology delivers advanced machine vision and quality inspection systems to ensure superior product quality. Our tailored solutions, featuring new and affordable machines, optimize manufacturing with precision and efficiency.

Get in Touch

Why Partner with TC Smart Technology?

Based in Delhi NCR - Noida, our certified engineers use platforms like Siemens, FANUC, and Cognex to deliver vision systems with 99% defect detection accuracy, 30% productivity gains, and ISO 9001/IATF 16949 compliance.

High-Accuracy Inspection

AI-driven systems achieve up to 99% defect detection accuracy.

Seamless Integration

Compatible with PLCs, SCADA, and robotic systems for automation.

IoT-Enabled Analytics

Real-time data reduces downtime by 25% with predictive maintenance.

Our Vision & Inspection Services

Comprehensive solutions for automated quality control, tailored for precision and efficiency.

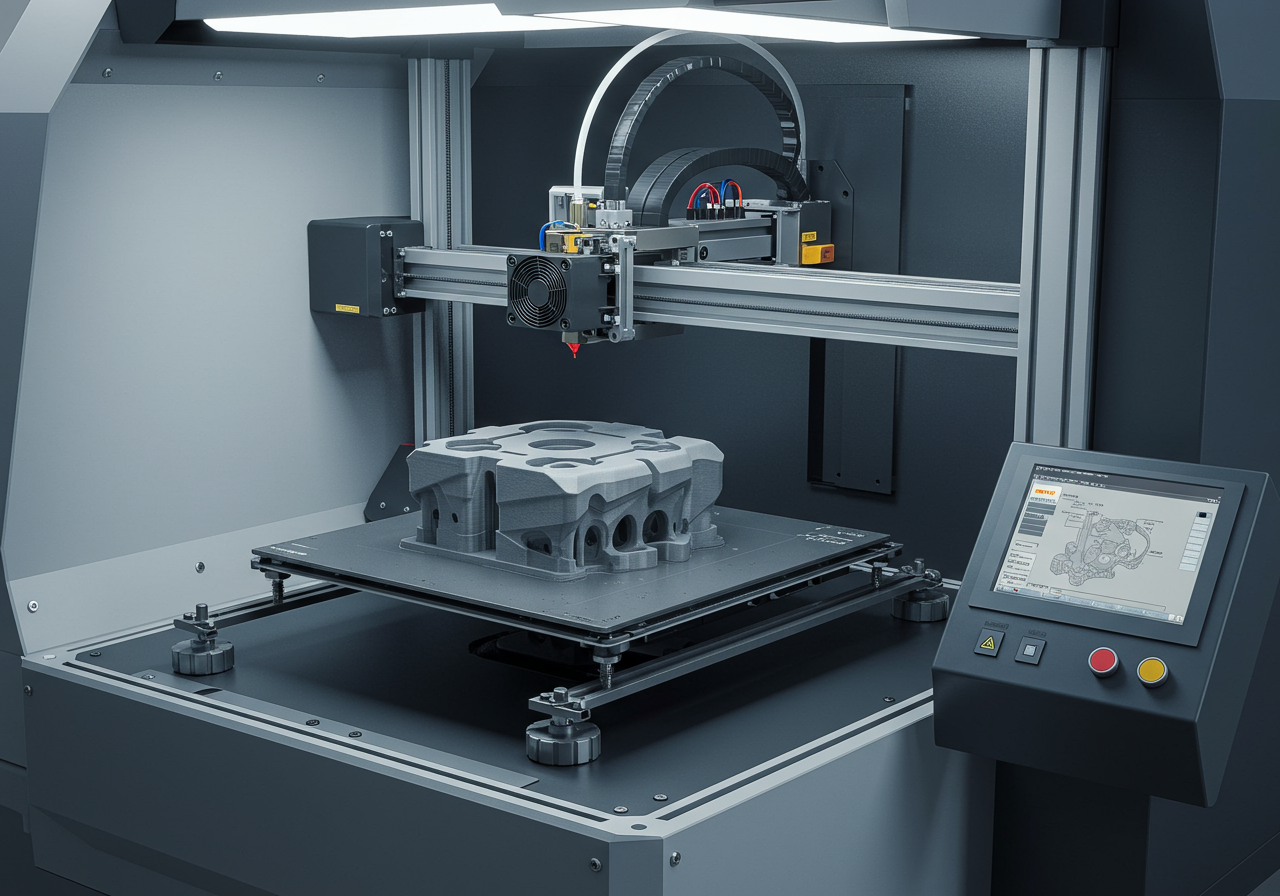

Custom System Design

Tailored vision systems for compatibility with your production line.

Defect Detection

AI-powered identification of flaws with 95% reject rate reduction.

Dimensional Measurement

Precise gauging with tolerances as tight as ±0.01 mm.

Assembly Verification

Imaging ensures error-free part assembly and alignment.

System Integration

Combines vision with PLCs, SCADA, and robots for automation.

Maintenance & Support

Proactive services ensure 99.5% uptime and reliability.

Industry-Tailored Solutions

Vision systems crafted for diverse industrial quality control needs.

- Aerospace: ±0.01 mm precision for airframe components.

- Automobile: 30% faster QC for engine parts.

- Medical: ISO 13485-compliant device inspection.

- Electronics: ESD-safe circuit board checks.

- Pharmaceuticals: GMP-compliant packaging verification.

- Power: QC for wind turbine blades.

- Railways: Safe railcar part inspections.

- Tele-Communication: Antenna mount checks.

- Oil & Gas: Durable valve inspections.

- EMS: Traceable connector QC.

- General Engineering: Flexible prototyping checks.

- More: Diamond & Jewellery, Die & Mould.

Technical Highlights

Advanced features powering our vision and inspection solutions.

- Platforms: Siemens, FANUC, Cognex.

- AI Processing: 20% fewer false positives.

- 3D Vision: ±0.01 mm accuracy for geometries.

- Speed: 100 fps real-time processing.

- IoT Connectivity: 25% downtime reduction.

- Compliance: ISO 9001, IATF 16949.

End-to-End Support

From installation to ongoing maintenance, we’re your quality control partner.

Installation & Setup

Seamless integration tailored to your facility, locally or globally.

Comprehensive Training

Equip your team with hands-on vision system expertise.

24/7 Support

Rapid response with remote diagnostics in under 4 hours.

Why Automate with Us?

Unlock measurable benefits for your quality control processes.

Minimized Defects

99% detection accuracy reduces rejects by 95%.

Boosted Productivity

30% higher output with automated inspections.

Enhanced Compliance

Meets ISO 9001 and IATF 16949 standards.

Cost Efficiency

20% lower energy costs with efficient systems.

Transform Your Quality Control Today

Ready to elevate your production with advanced machine vision systems? Contact TC Smart Technology at info@tcsmarttechnology.com or visit us in Delhi NCR - Noida.

Contact Us NowContact Information: Email: info@tcsmarttechnology.com | Location: Delhi NCR - Noida