Premier Battery Assembly, EV & Energy Sector Machines

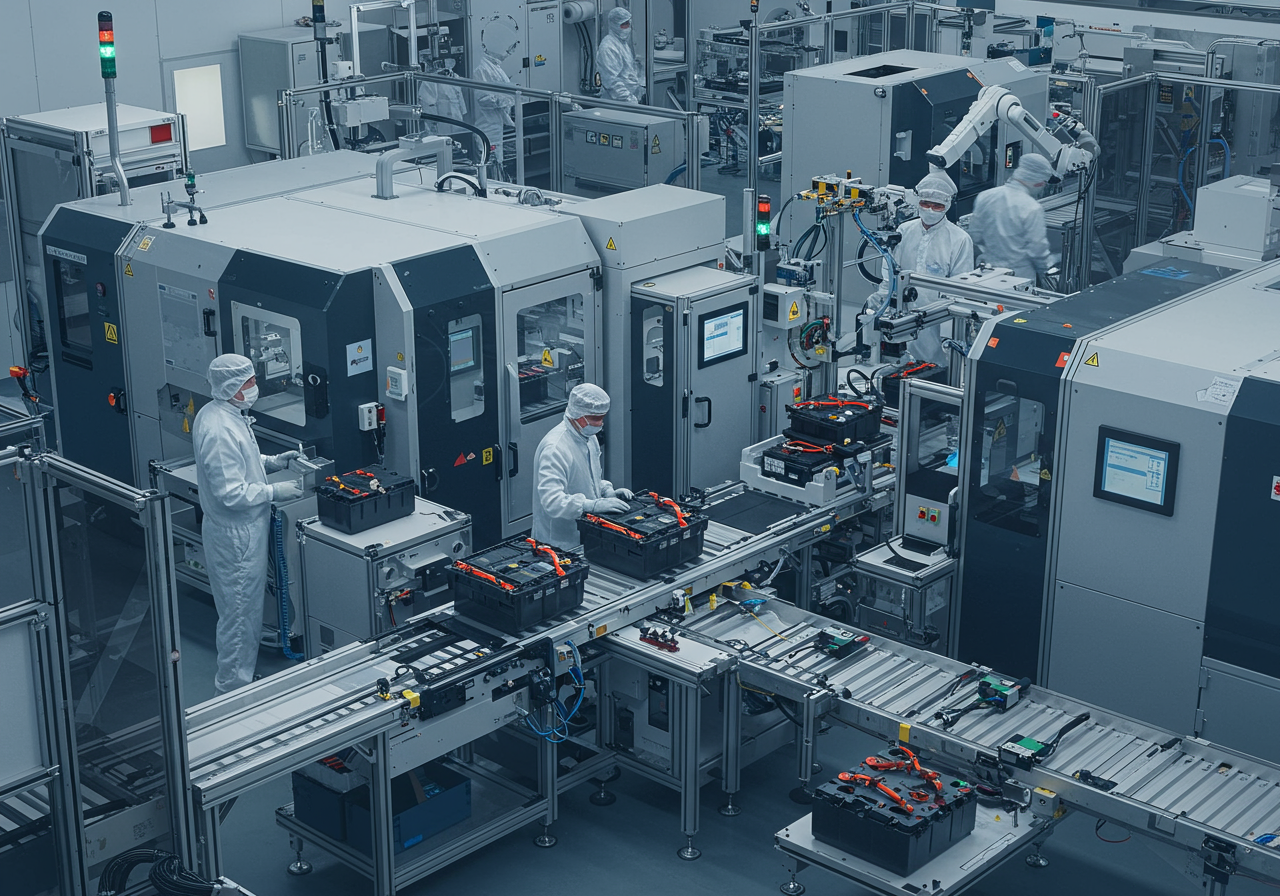

Premier Battery Assembly & EV Machines by TC Smart Technology

Headquartered in Delhi NCR - Noida, TC Smart Technology delivers reliable battery assembly, EV, and energy sector machines with advanced robotics, IoT connectivity, and ±0.02 mm precision. Our practical solutions optimize production for global industries.

Get in Touch

Why Choose TC Smart Technology?

From Delhi NCR - Noida, we provide reliable machines for battery assembly and EV production with proven automation, IoT integration, and 25% downtime reduction, ensuring efficiency, scalability, and Industry 4.0 compliance.

High Precision

Positional accuracy of ±0.02 mm.

Robotic Automation

6-axis robots improve throughput by 40%.

Energy Efficiency

20% less power with servo drives.

Our Battery Assembly & EV Machines

A diverse range of new, specialty, and affordable machines for battery and EV production needs.

Cell Assembly Machines

Up to 120 cells per minute for high throughput.

Ultrasonic Welders

Weld strengths up to 2,000 N in <1 second.

Laser Welding Systems

6 kW power for precise module welds.

Module & Pack Assembly

IP67-rated sealing for EV batteries.

Testing & Sorting Machines

99.9% defect detection accuracy.

Electrolyte Filling

Leak-free sealing with UN38.3 compliance.

Specialty Battery & EV Equipment

Practical solutions for unique production challenges.

- Robot Integration: 95% error reduction with 6-axis arms.

- IoT Monitoring: 25% less downtime with analytics.

- Vision Systems: 99% defect detection accuracy.

- Quality Control: Inline testing for welds and seals.

- Modular Lines: 50% faster setup changes.

- Traceability: ISO 9001-compliant data logging.

Industry-Specific Solutions

Tailored solutions for battery and EV manufacturing.

- Aerospace: Lightweight drone batteries.

- Automobile: IATF 16949-compliant EV packs.

- Medical: ISO 13485-compliant device batteries.

- Jewellery: Precision tool batteries.

- Electronics: Reliable BMS assembly.

- Infrastructure: Smart grid storage systems.

- Oil & Gas: Remote monitoring batteries.

- Power: Renewable energy storage.

- Railways: Electric locomotive batteries.

- Telecom: Telecom tower backup power.

- Agriculture: Electric tractor batteries.

- Die & Mould: Battery casing molds.

Technical Highlights

Proven features driving our battery and EV solutions.

- Production Capacity: 120 cells per minute.

- Precision: ±0.02 mm for stacking and welding.

- Controls: Siemens, Mitsubishi with Industry 4.0.

- Automation: 6-axis robots and vision systems.

- Materials: Lithium-ion, solid-state cells.

- Safety: UN38.3 and IATF 16949 compliance.

End-to-End Support

Complete solutions with machines, training, and 24/7 support.

Installation & Setup

Tailored setup for seamless integration.

Operator Training

Practical training for assembly and testing.

24/7 Support

Rapid response with <4-hour downtime.

Why Our Battery & EV Solutions?

Optimize your production with reliability and efficiency.

High Precision

±0.02 mm for cell assembly and welding.

Enhanced Productivity

40% faster cycles with automation.

Cost Efficiency

Affordable machines with high ROI.

Reliability

99.5% uptime with predictive maintenance.

Optimize Your Battery & EV Production

Ready to enhance your manufacturing with our battery assembly and EV solutions? Contact TC Smart Technology at info@tcsmarttechnology.com or visit us in Delhi NCR - Noida.

Contact Us NowContact Information: Email: info@tcsmarttechnology.com | Location: Delhi NCR - Noida