Premier Lathe & Turning Machines (Manual & CNC)

Premier Lathe & Turning Machines by TC Smart Technology

Headquartered in Delhi NCR - Noida, TC Smart Technology delivers cutting-edge lathe and turning machines (manual & CNC) with advanced robotics, IoT connectivity, and ±0.005 mm precision. Our comprehensive solutions redefine precision machining for global industries.

Get in Touch.png)

Why Choose TC Smart Technology?

From Delhi NCR - Noida, we provide innovative lathe and turning machines with AI-driven precision, IoT integration, and up to 50% cycle time reduction, ensuring versatility, scalability, and Industry 4.0 compliance.

Ultra-Precision

Positional accuracy of ±0.005 mm.

Robotic Automation

6-axis robots reduce cycle times by 50%.

Sustainability

25% less energy with efficient designs.

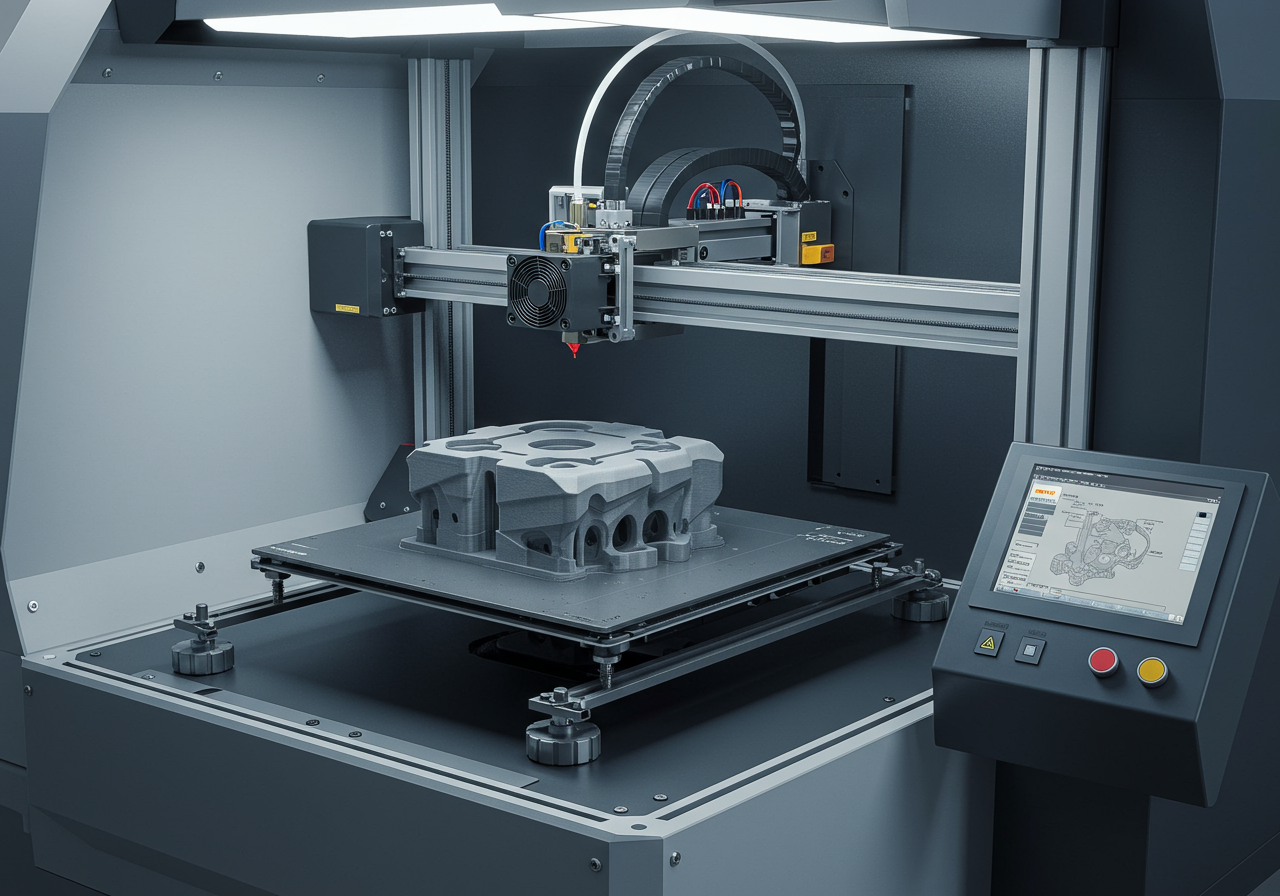

Our Lathe & Turning Machines

A diverse range of new, specialty, and affordable machines for all turning and machining needs.

Manual Lathes

Bed lengths up to 3,000 mm for custom work.

CNC Lathes

Multi-axis for complex geometries.

CNC Turning Centers

Live tooling for multi-tasking.

Swiss-Type Lathes

Micro-machining with 38 mm bar capacity.

Heavy-Duty Lathes

Up to 2,000 mm diameter workpieces.

Vertical Turning Lathes

High stability for oversized parts.

Specialty Turning Equipment

Advanced solutions for unique machining challenges.

- Robot Integration: 6-axis arms for 50% faster cycles.

- IoT Connectivity: 30% less downtime with analytics.

- Hybrid Systems: Turning-milling with Ra 0.4 µm finishes.

- High-Speed Lathes: 10,000 RPM for alloys.

- Cryogenic Cooling: Enhanced tool life for titanium.

- Multi-Turret: Simultaneous machining.

Industry-Specific Solutions

Tailored turning solutions for diverse industries.

- Aerospace: ±0.005 mm turbine shafts.

- Automobile: 40% faster crankshaft turning.

- Medical: ISO 13485-compliant implants.

- Jewellery: 0.01 mm mold precision.

- Electronics: EMI-shielded connectors.

- Infrastructure: Large bridge fittings.

- Oil & Gas: Corrosion-resistant fittings.

- Power: Turbine rotor machining.

- Railways: Durable railcar axles.

- Telecom: High-precision waveguides.

- Agriculture: Plow shaft durability.

- Die & Mould: 60 HRC mold bases.

Technical Highlights

Advanced features driving our turning solutions.

- Spindle Performance: Up to 10,000 RPM, 50 kW.

- Precision: ±0.005 mm positional accuracy.

- Controls: FANUC, Siemens with OPC UA.

- Automation: 6-axis robots and bar feeders.

- Materials: Metals, plastics, composites.

- Features: Live tooling, Y-axis support.

End-to-End Support

Complete solutions with machines, training, and 24/7 support.

Installation & Setup

Expert setup for seamless integration.

Operator Training

AR-based training for CNC programming.

24/7 Support

Rapid response with <4-hour downtime.

Why Our Turning Solutions?

Transform your operations with precision and efficiency.

High Precision

Tolerances as tight as ±0.005 mm.

Enhanced Productivity

50% faster cycles with automation.

Cost Efficiency

Affordable machines with high ROI.

Material Versatility

Metals, composites, and ceramics.

Revolutionize Your Manufacturing

Ready to transform your production with our lathe and turning machine solutions? Contact TC Smart Technology at info@tcsmarttechnology.com or visit us in Delhi NCR - Noida.

Contact Us NowContact Information: Email: info@tcsmarttechnology.com | Location: Delhi NCR - Noida